Tire Recycling Rubber Particles Plant

What kind of tires can be recycled into particles?

Loader tires

Pasenger tires

Other tires

Waste tire recycling mainly targets passenger tires, car tires, truck tires, wire tires, fiber tires and other waste materials containing rubber.

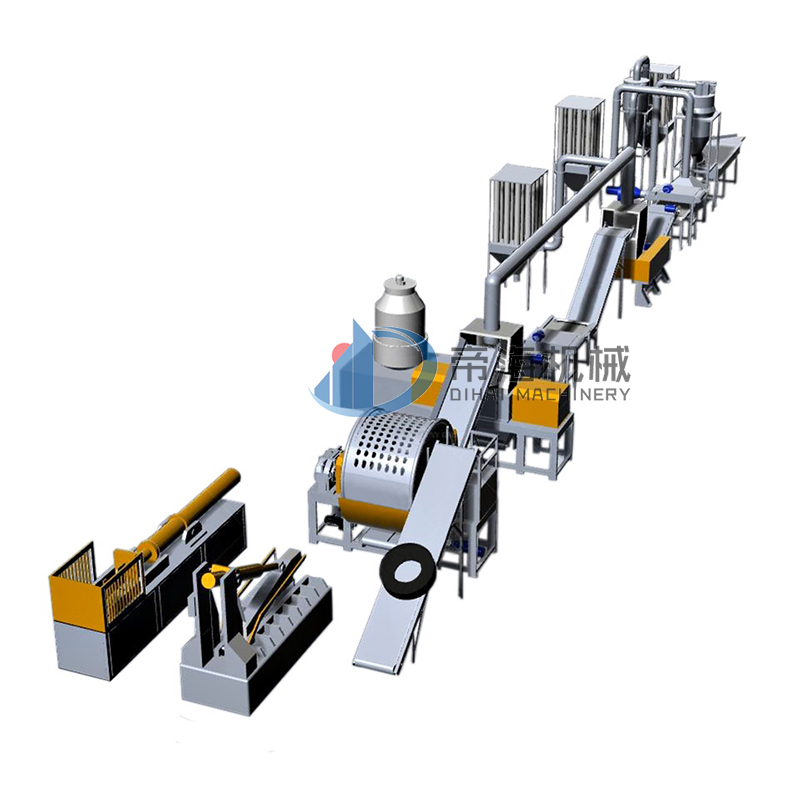

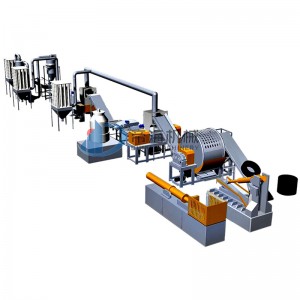

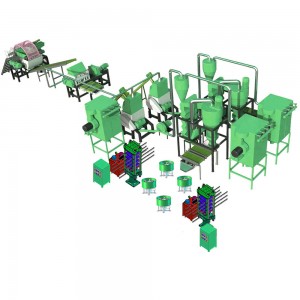

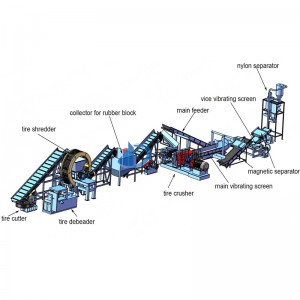

Process of tire recycling into granules

The recycling of waste tires is a complete recycling production system, which requires different tire recycling machines such as tire baler, tire debeader (tire drawing machine), tire cutting machine, tire shredder, steel wire separator (rasper), rubber granulator, magnetic separator, rubber particle screening machines, rubber grinding machine, conveyor, pulse dust collector, fiber separator ,rubber product pressing machine and so on. Not a tire recycling machine can fully realize the recycling production of tires.

Tire Debeader (Tire Drawing Machine)

The inner bead of a truck tire is a coarse steel wire, which is shredded directly by shredder wire, which will reduce the service life of recycling machinery such as shredders and wire separators. The role of the tire debeader is to remove the coarse steel wire directly, retaining the integrity of the steel wire, improve the recycling value.

Truck Tire Cutting Machine

The diameter of truck tires is large, direct shredder requires large tire shredder, resulting in high recycling costs. Truck tire cutting machine is mainly to truncate the truck tires, adapted to medium, and small tire shredder shredding.

Tire Shredder

Tire Shredder is to shred the whole tire or heavy-duty vehicle tire segments directly into tire chunks in preparation for separating steel wire and rubber. Depending on the customer's usage requirements, capacity, and recycling costs, tire shredders are available as large tire shredders, medium tire shredders and small tire shredders.

Steel Wire Separator / Tire Rasper

Tire is a composite, containing rubber, steel wire, fiber and so on. Steel Wire Separator is mainly to separate the tire pieces after shredding by tire shredder into steel wire and rubber pieces around 15mm mulch.

Magnetic Separator

Magnetic Separator is a machine that removes the steel wires from the rubber blocks /mulch crushed by the wire separator.

Rubber Granulator

Rubber granulators are used for crushing the rubber pieces (Mulch) after the steel wire separator to turn them into 0-5mm rubber granules.

Rubber Particle Screening Machines

Rubber Particle Screening Machines are used to screen and classify the 0-5mm rubber granules crushed by Rubber Granulator into 0-1mm, 1-3mm, and 3-5mm rubber granules to meet different recycling market demands.

Rubber Grinding Machine

Rubber Grinding Machine is mainly used to grind the pure rubber granules into rubber powder, which is used to make high-end rubber products.

Conveyor

Conveyors are used to connect the various recycling machines, contributing to the integrity of the tire recycling line and the normal operation of production.

Pulse Dust Collector

The Pulse Dust Collector is used to clean the air by sucking up and removing dust, fibers, etc. generated during the operation of the tire recycling line.

Fiber Separator

The purpose of the Fiber Separator is to completely remove fibers from the rubber granules to achieve 99.99% purity of the rubber granules.

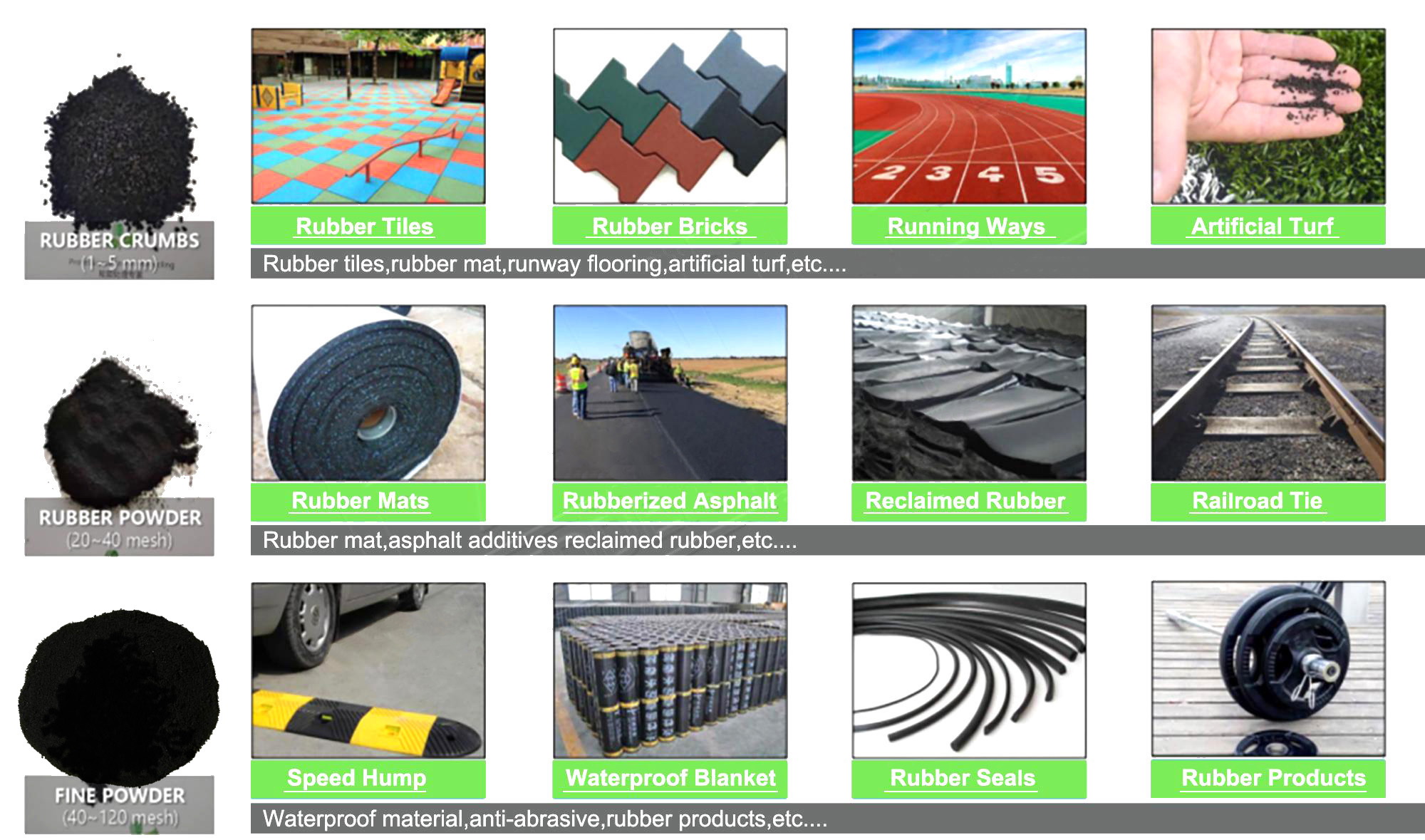

Recycling Rubber Products Display

We are building a sustainable future with the Tire Recycling Plant. Final products are for infill artificial grass, poured in place, bark for mulch - colored rubber granules, rubber athletic tracks, rubber tennis courts, rubber bowls courts, rubber paratroopers, rubber building soundproofing, rubber playgrounds, rubber pavement, traffic warning products, sports products, new tires and so on.

FAQ of tire recycling rubber particles plant:

What Tire Can The Tire Recycling Plant Handle?

All types are allowed, like car tires, truck tires, other rubber products and so on. The open top allows continuous feeding. If continuously loaded and operating optimally.

How Is The Tire Recycling Plant Powered?

The shredder is powered by 3 phases. It has a noise level of 75 db(A). For more information about the technical specifications of the machines, please ask our sales team.

What Are The Markets For Recycled Materials?

There are basically two types of derived product markets, commodity materials and value-added materials.

What are the markets for tire recycled materials?

There are two types of tire-derived product markets, commodity materials and value-added materials. For Example:

- Primary Shredder – Tire Derived Fuel (TDF) chips.

- Mulch Shredder – Low metal content TDF (smaller chips with less metal), rubber nuggets for mulch markets.

- Granulator – Crumb Rubber used as infill (dirt) in artificial turf systems.

- Rubber Mill – Rubber Powder used in place of SBR in rubber-modified asphalt.

What are the stages of tire recycling?

Generally speaking, most US and European tire recycling machinery manufacturers utilize a 5-6-step approach to tire recycling.

- Step One is to remove ring steel wire and cut the whole tie into segments(optional stage).

- Step Two is to shred the tire or segment into small blocks.

- Step Three is to crush the tire blocks into rubber mulch,This is the stage where the majority of the wire in the tire is removed.

- Step Four is to granule rubber mulch into rubber particals.At this stage the remaining embedded wire and fiber is removed.

- Step Five is to grind the pure rubber particles into rubber powder.

- Step Six is to use recycled rubber to make rubber products.

What is the guarantee period of tire recycling plant?

Our guarantee that goods is completely brand-new and shall conform to the technical specifications as stipulated. The mechanical guarantee except the Buyer`s improper use and wear parts is 12 months or 18 months from the date of picking up goods in case the installation cannot be finished due to the Buyer's fault.

What is the after-sales service of tire recycling plant?

- Di Hai Machinery understands that your equipment needs to be functioning efficiently and consistently for your success. We offer comprehensive training and instruction for any equipment operation, operations consultation, and market information.

- On-site consultation and facility operations review if necessary.

- Remote technical assistance and diagnostics.

- Professional seminar and webinar sessions and events.

- For additional information on our exclusive training support and seminars, please contact the Di Hai Machinery Team.

How Is Di Hai Machinery Equipment And The Machinery They Manufacture Different From Other Recycling Equipment Manufacturers?

Di Hai Machinery took the approach of designing machines specifically to process in the most efficient, cost-effective way possible. In doing so we have developed machinery that is easier to and less costly to maintain, while delivering superior quality materials at a lower cost per ton.

|

Model |

Power |

Capacity |

Operation |

Adaptable Tire |

Discharge |

|

TRL03 |

78 Kw |

100-300 Kg Per Hour |

Semi-Auto/ Auto |

Car Tires, Truck Tires |

Rubber Particles, Rubber Powder, Steel Wire, Fiber. |

|

TRL05 |

97 Kw |

300-500 Kg Per Hour |

Semi-Auto/ Auto |

||

|

TRL08 |

113 Kw |

500-800 Kg Per Hour |

Semi-Auto/ Auto |

||

|

TRL10 |

136 Kw |

800-1000 Kg Per Hour |

Semi-Auto/ Auto |

||

|

TRL12 |

158 Kw |

1000-1200 Kg Per Hour |

Auto |

||

|

TRL15 |

210 Kw |

1200-1500 Kg Per Hour |

Auto |

||

|

TRL20 |

260 Kw |

1500-2000 Kg Per Hour |

Auto |

Effects of tire recycling:

Tire recycling to blocks:

Tire recycling to particles:

Tire recycling to powder:

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.