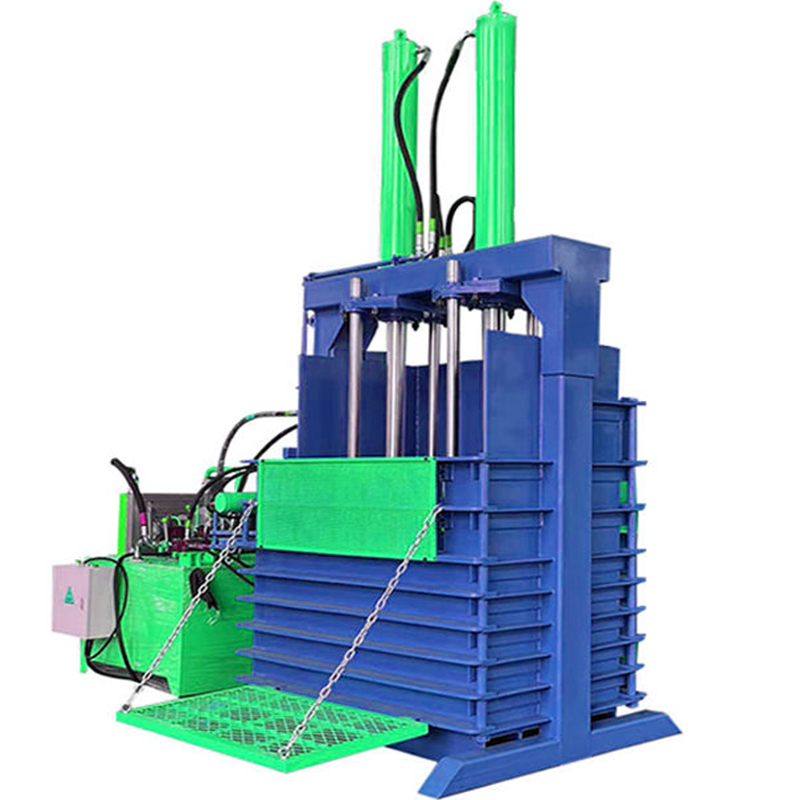

Tire Baler

Our standard tire baler / tyre baler machine represents a heavy-duty vertical baling machine, perfectly suited for compacting recycled tires into densely packed bales. These bales find new life as a versatile construction material used in applications such as oil refining, road foundations, lightweight embankment fillers, drainage layers, landscaping projects, and various civil engineering endeavors.

Tire baler application:

Car tires or passenger car tires, truck tires, jeep tires, bicycle tires, motorcycle tires, etc.

Tire baler features:

●Hydraulically driven door opening and closing ensures safe operation and makes opening and closing the door more convenient

● Unique pressure plate design, when the material is placed unevenly, the pressure plate is protected from damage by pressing with parallel bars at different frequencies.

●The entire system is manually controlled, easy to operate, and ensures durability

●Telescopic bullet-proof hook prevents tire rebound

● Fully automatic bag hanging chain, easier to operate and ensure higher efficiency

● Front and rear opening doors make bundling and unpacking easier

Shipping site:

|

Model |

DH-120 |

||

|

Motor |

18.5kw |

||

|

oil pump |

63 high pressure quantitative plunger pump |

||

|

Main pressure cylinder

|

Main pressure cylinder | Outer diameter Ф194mm-1200mm *2 | |

|

preset pressure :20MPa |

|||

|

Control System |

Start cabinet + manual operating lever |

||

|

Hydraulic oil grade |

46# anti-wear hydraulic oil |

||

|

Fuel tank capacity 300L |

|||

|

Packaging line |

Steel wire/gold wire rope |

||

|

Machine parameters |

Machine specifications |

(Length * Width * Height) 1600*1300*3800mm |

|

|

Feeding port size |

(Length * Width)1200*800mm |

||

|

Silo size |

(Length * Width * Height)1200*800mm |

||

|

mass density |

≥330KG/m³ |

||

|

Output |

1600-3600kg/hour | ||

|

Feeding method |

Can be loaded manually or by conveyor |

||

|

Machine weight |

About 4.5T | ||

|

Bale weight |

400-600kg | ||

Effects for tire baler:

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.