Single Shaft Shredder

A single shaft shredder is an industrial machine used to reduce the size of various materials through a cutting process. Unlike its double shaft counterpart, it features a single rotating shaft equipped with cutting blades. Materials are fed into the shredder and are cut by the high-speed rotating blades. It is also called one shaft shredder machine.

Single Shaft Shredder Applications:

Plastic: Plastic lump, plastic pipe, plastic sheet, PE film, PP woven bag, PET bottle, raffia, twine

Wood: Wood pallet, wooden box, timber residues

Paper Product: Waste paper and confidential documents

Scrap Metal: circuit board, aluminum casing, copper, radiator, wire, cable, WEEE

Mixed Waste: MSW(municipal solid waste) and RDF (refuse-derived fuel) production

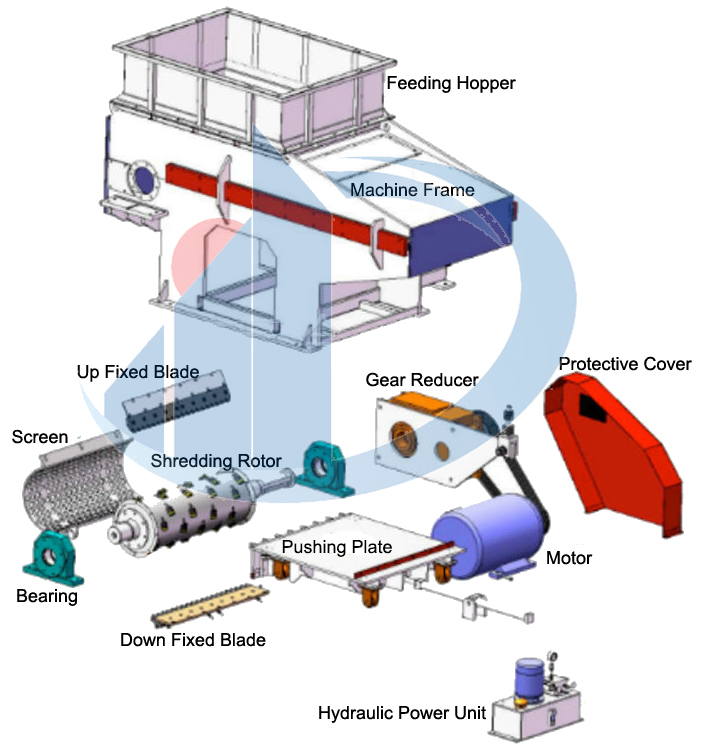

Working Principle of Single Shaft Shredder

The motor drives the knife shaft to drive the knife to rotate quickly. The feeder pushes the material into the crushing chamber between the movable knife shaft and the fixed knife. The blade on the knife shaft cooperates with the fixed knife to cut and tear the material for crushing. Unqualified materials are The blade is brought back to the crushing area to continue crushing, and the material with the discharge size falls from the screen to achieve the crushing purpose. The size of the blade and the size of the opening of the screen are selected according to the user's requirements, and the screen can be replaced according to the requirements of the discharge particle size.

Performance Characteristics

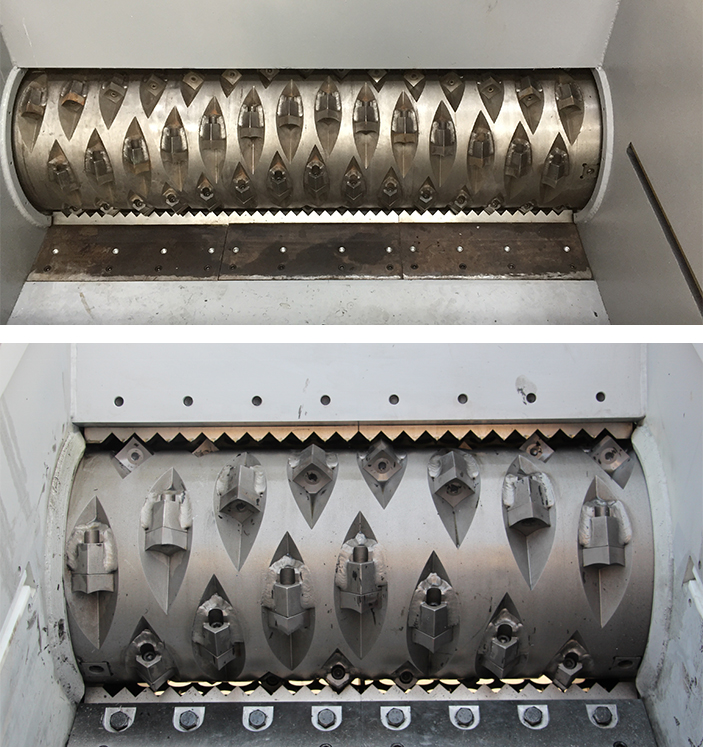

> Rotor knife adopts DC53 steel and counter knife adopts D2 steel.

> Main electrical components are trusted brands such as Siemens and Schneider.

> Automatic-reverse system re-orients rotor direction in case of motor overload and material jam.

> Easy access to rotor and screen, and quick to change them.

> Rotor knives can be used 2 times before being replaced, reducing operating costs.

> The gap between the counter knives and the rotor is adjustable.

> Several models of the screen are available and easily interchangeable.

Effect & Features

>The shredded cavity is deep and has no dead zone, which improves the feeding capacity and output;

>Its shredded ratio is large, and the product granularity is uniform;

>The transparent discharge port adjusting device can be convenient and increase the flexibility of the device;

>The lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small;

>Simple structure, reliable work and low operating costs;

>Equipment energy saving: single machine energy saving 20% ~ 30%;

| Model | 600 | 800 | 1000 | 1200 |

| Machine Power | 22KW | 45KW | 55KW | 75KW |

| Hydraulic Power | 3KW | 4KW | 5.5KQ | 5.5KW |

| Reducer | H4 Hard Surface Gear | H5 Hard Surface Gear | H7 Hard Surface Gear | H8 Hard Surface Gear |

| Control Cabinet | PLC | PLC | PLC | PLC |

| Hydraulic Cylinder Stroke | 600mm | 800mm | 1000MM | 1200MM |

| Pressure-Sensitive | 6-12Mpa | 6-12Mpa | 6-12Mpa | 6-12Mpa |

| Feeding Port Size | 1210x1210mm | 1420x1500mm | 1420x1700mm | 1420x1900mm |

| Exquisite Height | 480mm | 480mm | 480mm | 480mm |

| Shredding Cahmber | 600x600mm | 800x900mm | 800x1000MM | 1000x1200mm |

| Moving Blade size | 40x40mm | 40x40mm | 40x40mm | 40x40mm |

| Numbers | 30pcs | 45pcs | 60pcs | 75pcs |

| Fixed Blade size | 300x100mm | 400x107mm | 500x113mm | 600x120mm |

| Numberts | 2pcs | 2pcs | 2pcs | 2pcs |

| Blade Hardness | HRC50°- HRC55° | HRC50°- HRC55° | HRC50°- HRC55° | HRC50°- HRC55° |

| Principal Axis | φ140x1000mm | φ150x1200mm | φ180x1400mm | φ190x1600mm |

| Axis Speed | 75 rpm | 75 rpm | 75 rpm | 75 rpm |

| Dia.of Blade Rest | 260mm | 300mm | 400mm | 400mm |

| Rotor size | 310x600mm | 350x800mm | 450x1000mm | 450x1200mm |

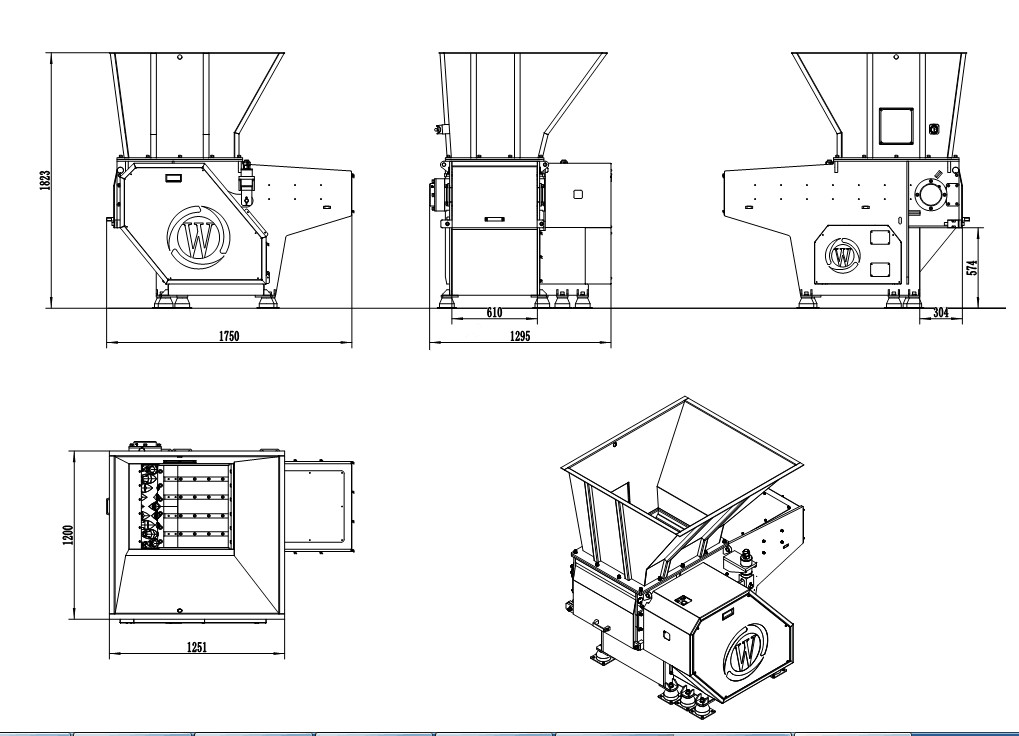

| Dimensions | 2200x1400x1900mm | 2800x1700x1900 | 3400x1800x2200mm | 3600x2000x24000mm |

| Weight | 2850kg | 3100kg | 3800kg | 4200kg |

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.