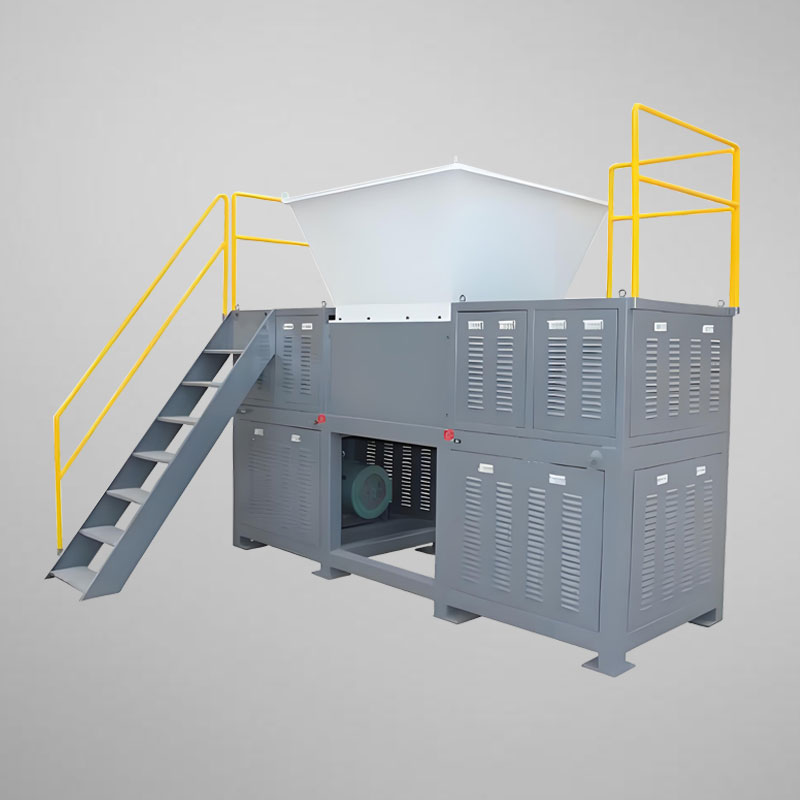

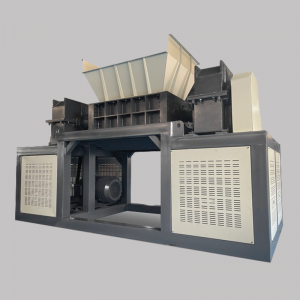

Plastic Shredder

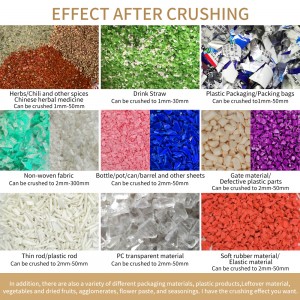

Plastic Shredder Applicable Materials:

1. Various hollow containers: plastic beverage cans, plastic barrels, iron cans, packaging boxes.

2. Waste household appliances: TV, washing machine, refrigerator shell

3. Pipe material: large pipe, pipe fitting and PE pipe

4. Waste formwork: wooden pallets, plastic pallets, and truck pallets

5. Waste tires: Automobile tires, truck tires

6. Scrap metal: automobile shell, aluminum alloy die casting waste, engine shell, gearbox, lead, and steel plate with thickness less than 5mm.

7. Food waste, garbage, animal carcasses, RDF derivatives, medical waste, biological straw, and garden waste.

8. Rubber head material, paper mill rope, waste paper, corrugated paper.

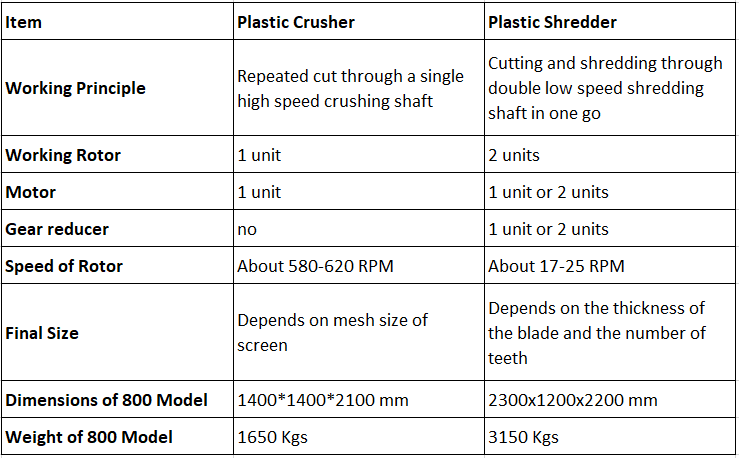

Pastic shredder is a machine used to break down plastic waste into smaller pieces or flakes. This process facilitates easier handling, recycling, or repurposing of plastic materials. Engineered by our top experts in the shredding industry, your company can greatly benefit from the acquisition of the high-quality plastic shredding machine. This is a powerful plastic shredder machine that provides you with excellent versatility and high performance, making it the ideal choice for your business. It is more than capable of shredding through the tougher materials, rendering them into a smaller, easier-to-manage shred size. This plastic shredder is designed to surpass your expectations, offering superior strength and optimal usage that allows you to outperform in the shredding industry. It provides improved efficiency while minimizing your footprint, allowing you to diversify your business.

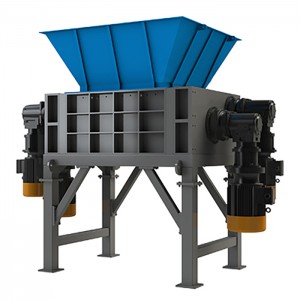

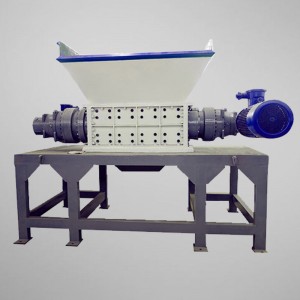

Details of Plastic Shredder Machine

Bearing seal is unique multiple combination sealing structure effectively blocks the contact of broken material and grease. The liquid material can protect the bearing, gear, ensuring continuous and stable operation of machine.

Feed hopper: high quality carbon steel plate, laser precision cutting. The optimal slope design effectively reduces feed shocks and allows for smooth feeds.

Motor: Chinese or international famous brand, 100% copper movement, strong power, long life

Reduction Gears Reducer: saving space, withstanding overload capacity. It is low energy consumption, high performance, and efficiency up to 95 or more. Small vibration, low noise, select excellent section steel material, steel cast-iron box, gear surface after high-frequency heat treatment

The blade is made of alloy tool steel, has a high hardness of quenching, more abrasion and impact resistance, longer service life, reducing the frequency of blade replacement.With a multi-teeth design,the shredding effect is significant, Modern installation is more convenient to maintain.

The shredding chamber is processed by the overall CNC, with less error and high accuracy, The shredding chamber is a modular installation and the bolt is fixed to reduce vibration and response, Arc-sharped partitions are installed on both sides of the chamber to ensure smooth discharge and increase capacity.

How does plastic shreder work?

Inside the shredder, rotating blades or knives cut the plastic into smaller pieces. These blades can vary in design, including single-shaft, multi-shaft, or granulator styles, depending on the desired output size and type of plastic being processed.

Discharge Out: Shredder is a full pass rate machine without screen bottom. The plastic shredder will discharge the material continuously according to the feeding condition.

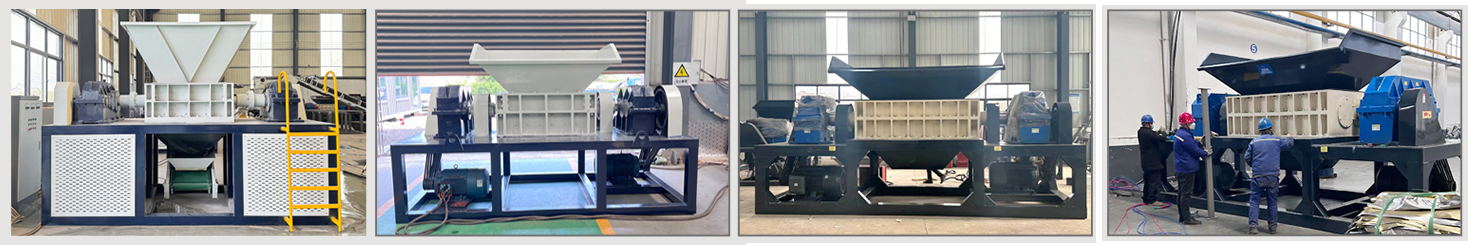

Installation: The floorspace of the plastic shredder covers a smaller area and requires a 3-phase connection. In view of the installation of the whole machine, or retain power and shredding parts, almost no additional installation, is directly connected to the power supply. Our technician will guide the installation process.

Load: The open top allows continuous loading of waste. Fully automatic control of the PLC distributes power output according to feeding conditions. If overload occurs, the plastic shredder will automatically flip over, and then continue to cycle.

Plastic Shredder Perfect for your Field

Plastic Shredding Machine for the Recycling Industry

Plastic Shredder for Logistics & Distribution Centres

Plastic Shredder in Large Supermarkets & City

> A plastic shredder strategically installed in a recycling facility becomes an integral part of the working process.Like Aluminum & Copper Recycling, Battery Recycling, E-Waste Recycling, General Waste Recycling, Medical Waste Recycling, Metal Recycling, Paper Shredding, Plastic Recycling,Textiles & Carpet Recycling, Tire Recycling, Wood Recycling and so on.

> Logistics and distribution centers process huge amounts of plastic and cardboard packaging as good as received and distributed.

> In order to increase recycling value, after separating, the plastic shredding machine can shred them into blocks,then easy to store and transportation.

> Large supermarkets and living cities handle a huge volume of packaging waste from consumer goods, food, and other perishable items.

> A plastic shredding machine is the ideal shredder to appropriately handle large volumes of mixed recyclable waste. The process can easily be managed by regular staff.

Features & Benefits

1. Blades: Various blade configurations (single-shaft, multi-shaft, or granulators) ensure effective cutting and size reduction. Some shredders allow for blade adjustments to control the size of the shredded material.

2. Hopper Size: Varies to accommodate different volumes of input material, from small batches to large-scale operations.

3. Gearbox: Enhances torque and efficiency, especially in heavy-duty shredders.

4. Emergency Stop: Provides quick shut-off in case of malfunction or safety concerns.

5. Protective Covers: Prevents accidental contact with moving parts and ensures operator safety.

6. Robust Construction: Made from high-strength materials to withstand the stress of shredding tough plastic materials.

7. Wear-Resistant Parts: Includes hardened blades and durable components to extend the lifespan of the shredder.

8. Replaceable Parts: Modular design for easy replacement of blades and other wear parts.

Lowest Cost per Ton to Buy

1. Customize your shredder line to meet your unique requirements

2. Invest in more equipment than you need

3. Get the right shredder for the job

Lowest Cost per Ton to Operate

1. High tolerances and precision cutting requires less horsepower

2. Built for smooth and efficient operation to last you decades

3. Engineered to be simple yet robust

4. More run time with less maintenance and hassle

5. Re-sharpenable and long-lasting blades

Lowest Cost per Ton to Maintain

1. Less mechanical interference for more machine up-time, more throughput, and fewer headaches

2. Leverage your own maintenance team- No specialty tools required

3. Quick blade change-out time

4. Blades last for roughly 1 million tires before needing sharpened

Optional Accessories for Plastic Shredder

In order to experience the optimal performance of the plastic shredder, we offer a wide variety of available optional accessories. These components, which include the hopper, in-feed conveyor, out-feed conveyor, and stand, are designed to enhance the overall performance of the plastic shredder so that it works at maximum capability. For more information on the other types of optional accessories that we have available, you can contact the sales team, who can help create the ideal shredding solution to your business.

Heavy-duty Seal Hopper

Observation Walk

Metal Separator

Plate Chain Conveyor

Hydraulic Press Design

Pulse Dust Collector

|

Model

|

600-300-44-HD

|

800-400-60-HD

|

900-400-74-HD

|

1000-450-45-HD

|

1200-500-110-HD

|

1400-600-150-HD

|

|

Shredding Box

|

Adopts Upper And Lower Shells, Steel Plate Bolted Structure

|

|||||

|

Size of Feeding Port(mm)

|

1000×800

|

12000×1000

|

1300×1000

|

1400×1100

|

1600×1200

|

1800×1400

|

|

Working Capacity(T/H)

|

About 1

|

About 2

|

About 3

|

About 4

|

About 6

|

About 10

|

|

Rotational Speed

|

9-12 r/min (according to shredding material)

|

|||||

|

Shredder Structure

|

Square Steel Pipe, Steel Plate, Casting Parts

|

|||||

|

Weight(Kg)

|

3200

|

4300

|

5800

|

8600

|

12500

|

15700

|

|

Hardness of Blade

|

HRC50°- HRC55°

|

|||||

|

Type of Blade

|

Outer Multi-Toothed, Inner Hexagon

|

|||||

|

No-Load Noise

|

In 1meter ≦75 db.(A)

|

|||||

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.