Plastic Film Shredder

Features of plastic film shredder:

1. The blade on the rotor is detachable for easy cleaning, maintenance and maintenance;

2. The movable knife adopts the “V”-shaped installation method, which cuts evenly during the entire shredding work, reduces energy consumption and reduces noise;

3. Each movable knife has 4 cutting edges, which can be rotated 90° to continue use after wear; each fixed knife has 2 cutting edges, which can be rotated 180° to continue using after wear; strengthen the replacement of the movable knife and the fixed knife Sex and life cycle, reducing costs;

4. The main shaft is driven by a gear reducer, running smoothly, with low noise and large torque;

5. Equipped with hydraulic reciprocating pushing material power system, with firm structure and stable operation;

6. The entire system is controlled by the PLC program, which can automatically rotate forward and reverse, and stop, making the machine safer and more reliable.

| Item | 600 | 800 | 1000 | 1200 |

| Machine Power | 22KW*2 | 22/30KW*2 | 37KW*2 | 45KW*2 |

| Reducer | H4 Reducer of Hard Tooth Surface | H5 Reducer of Hard Tooth Surface | H7 Reducer of Hard Tooth Surface | H8 Reducer of Hard Tooth Surface |

| Capacity | About 800 kg per hour | About 1000 kg per hour | 1500 kg per hour | About 2500 kg per hour |

| Control Cabinet | PLC | PLC | PLC | PLC |

| Feeding Port Size | 1000x1000mm | 1200x1000mm | 1400x1100mm | 1600x1200mm |

| Shredding Cahmber | 600x750mm | 800x750mm | 1000x800MM | 1200x800mm |

| Moving Blade Size | 40x40mm | 40x40mm | 40x40mm | 40x40mm |

| Numbers | 60pcs | 76pcs | 92pcs | 116pcs |

| Fixed Blade Size | 300x100mm | 400x107mm | 500x113mm | 600x120mm |

| Numberts | 8 pcs | 8 pcs | 8 pcs | 8 pcs |

| Blade Hardness | HRC50°- HRC55° | HRC50°- HRC55° | HRC50°- HRC55° | HRC50°- HRC55° |

| Principal Axis | φ140x1000mm*2 | φ150x1200mm*2 | φ180x1400mm*2 | φ180x1600mm*2 |

| Axis Speed | 90 rpm | 90 rpm | 87 rpm | 75 rpm |

| Dia.of Blade Rest | 280mm | 280/300mm | 280/300mm | 400mm |

| Rotor size | 310x600mm | 350x800mm | 350x1000mm | 450x1200mm |

| Dimensions | 2200x1400x2000mm | 2800x1700x2000 | 3400x1800x2200mm | 3600x2000x22000mm |

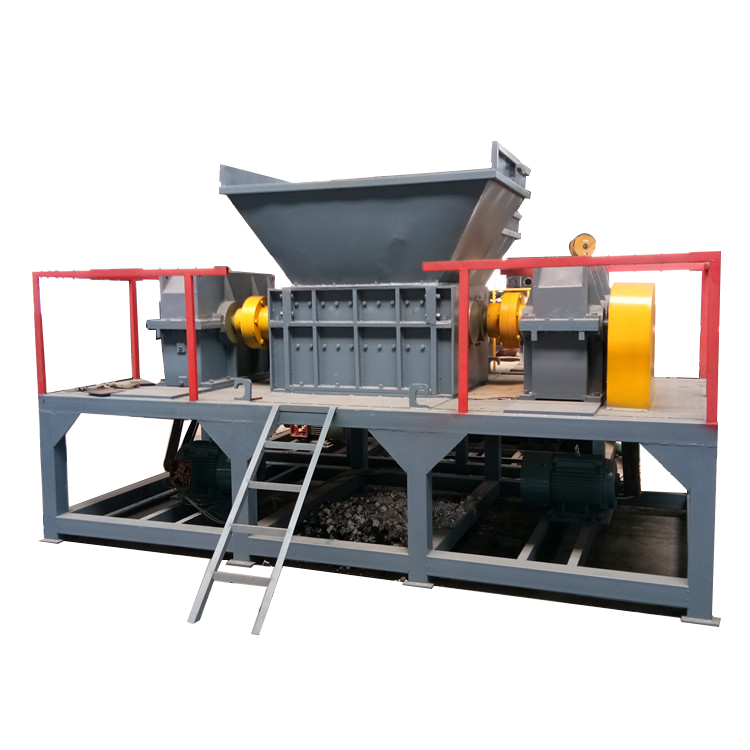

Working site:

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.