Plastic Crushing and Washing Plant

Recyclable Plastics Include:

* LLDPE/LDPE/HDPE film, crushed material

* PP/OPP/BOPP/CPP film, woven bags, jumbo bags, non-woven fabric (melt blown)

* PA66 fishing net, carpet

* PET/BOPET bottle flakes, film, waste cloth, foam, optical film

* EPS/XPS/EPE/PU/PVC crushed material, cold briquetting foam, hot melt foam, compacted foam, insulation board

* HIPS/PS/ABS home appliance housing, electronic waste, factory plastic

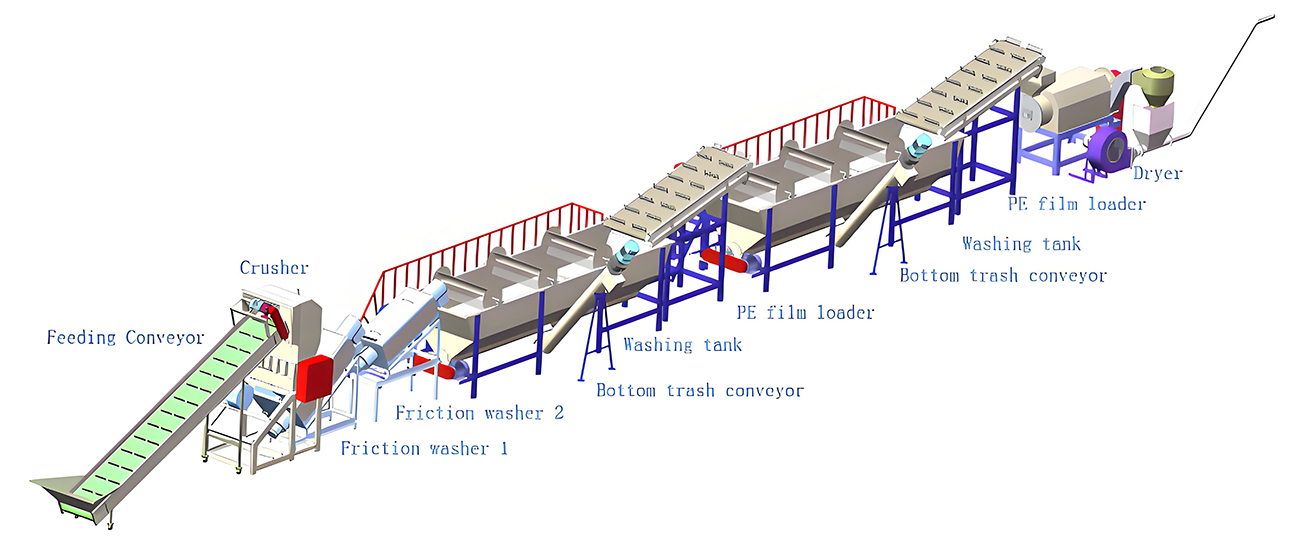

Main parts for plastic crushing and washing plant

Conveyor Belt with Metal Detector

Function: Feeding material and detection of the metal.

Semi-Automatic model for ferrous and non-ferrous, it is installed on the sorting conveyor Once there is metal passing it, it will alarm and stop the sorting conveyor, after picking out the metal then start it again.

Precision for Ferrous >2.5mm

Precision fornon-Ferrous>3.2mm

Plastic Crusher Machine

Function: Crushing the material into small flakes

With a water inlet do wet crushing

This series of blades is wider, which will save the blade's cost

Use the big roller bearing to ensure it is long time

The bearing house is outside of the crusher chamber so no dirty goes inside for longer use

The machine up chamber is higher and covered by a belt no flakes pop out

Friction washing loader

Function: Friction washing with water to remove the dirty and loading up it

Up and down both mounted with bearing design

With a water injection system to clean the screen

Bottom with water drain system

Washing off the dirty and loading the material out to the next step of processing

Floating washing tank

Function: Floating Washing separates the sand, soil and other dirty

The roller is specially made can have more

Roller Speed adjusted by inverter

The roller is specially made can have more washing for lakes but less water take out

Bottom with a conical design easily and better drains out the dirty and maintenance

With platform one set on the side of the tank

High-speed dewater machine

Function: take out dirty and remove water

With the roller bearing fixed outside of the rotor for long use life

Bearing is an “NSK” Brand in Japan

With water to wash the screen

Clean the screen with a rotating brush

Bottom with dirty water drain out

With water to cool the bearing house

The chamber is easy to open for maintenance

Inside with mesh layer, mesh diameter: 3 mm

With a water spray system to clean the mesh

Hot air dryer system

Function: drying the material heating by electricity box

Drying pipe: 1 set

Heating power box: 1 set

Heating power: 48KW

Drying pipe diameter: 219mm

Drying pipe length: 15m

Blower power: 7.5KW

|

Model

|

Capacity

|

Consumption Power

|

Hot Washing

|

Water Supply

|

Manpower

|

Area Required

|

|

DH-300

|

300 kg/hr

|

70 kw/h

|

Optional

|

4-5 m3/hr

|

2-3 Person

|

40*4*5 m

|

|

DH-500

|

500 kg/hr

|

140 kw/h

|

Optional

|

6-8 m3/hr

|

2-3 Person

|

40*4*5 m

|

|

DH-1000

|

1000 kg/hr

|

280 kw/h

|

Optional

|

8-10 m3/hr

|

3-4 Person

|

55*6*6 m

|

|

DH-1500

|

1500 kg/hr

|

350 kw/h

|

Optional

|

10-15 m3/hr

|

4-5 Person

|

78*6*6 m

|

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.