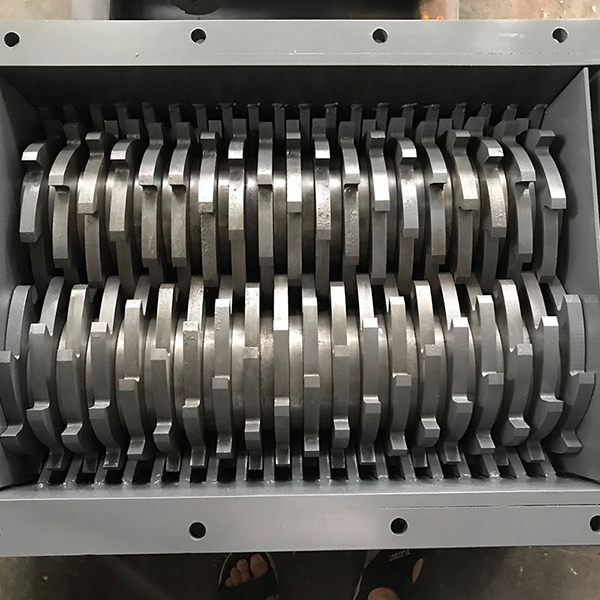

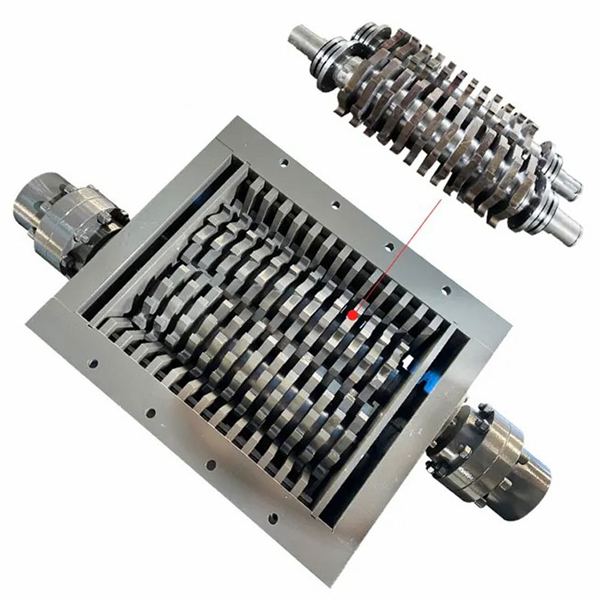

The recycling of rubber tires has become a complete industrial chain. In this industrial chain, tire shredders are an extremely important link. The annual amount of rubber tires discarded is astonishing. The tire shredder can shred the entire tire after the wire stripping. The rubber shredded by the tire shredder can be recycled and reshaped after layer-by-layer processing. The blade plays a very important role in the tire shredder. Keeping the blade in an ideal state will be of great significance to the shredding work.

Di Hai introduces the specific details of blade maintenance here. Following the advice of Di Hai Machinery can make the tire shredder work better and extend the service life of the blade. In the work of the tire shredder, the material input of the equipment should be carried out according to the manufacturer’s design of the equipment. The large production volume should be ensured to ensure that the input within the large production volume cannot exceed the approved production volume, because the excessive input will exceed the design processing volume of the equipment, and the equipment load is too large. Although the production volume can be increased in the short term, it will have a huge impact on the blade of the shredder and accelerate the wear of the blade of the tire shredder.

Tire shredders should be regularly inspected and repaired to check the status of the blades, and worn blades should be found in time to ensure that the performance of each blade is not much different. Some blades should not be too poor to affect the overall production. After the tire shredder is put into production for some time, the wear of the cutter is inevitable. The cutter can be polished, repaired and reused. As an important part of the tire shredder, considering that the tire shredder blades often shred dozens of waste products when in use, the high complexity of shredding can easily cause the wear of the shredder blade edge.

Once the tire shredder cutter is blunt, the shredding effect will become very poor. At this time, it is necessary to replace the spare cutter and disassemble the blunt cutter for grinding. As a shredder manufacturer, Jike Precision Knife Factory also has its own experience in grinding the tire shredder cutter. The wear of the blade is mainly the wear on the claws. The simple way to grind is to use a polishing machine to grind the inside of the blade until the blade edge is sharp. The arc of the claws should be strictly planed and perpendicular to the plane of the tire shredder blade, so that the loss of the original cutter body is small.

Post time: Sep-10-2024