Industrial Dryers

Types of industrial dryers:

Industrial dryers can be divided into triple rotary dryers, long rotary dryers, and airflow dryers.

Triple Rotary Dryers

Long Rotary Dryers

Airflow Dryers

Three-pass dryer

Three-pass dryer, also known as a high-efficiency combined three-drum dryer, is a high-efficiency and energy-saving drying equipment. Its main feature is to achieve a circulating self-insulating structure by nesting three concentric cylinders with different diameters, thereby improving thermal efficiency and drying effect.

Features of thress-pass dryer:

- High efficiency and energy saving: The thermal efficiency is improved by more than 40% compared with the traditional single-drum dryer, the coal consumption is 1/3 of the single-drum dryer, and the electricity saving is 40%.

- Environmental protection: The exhaust gas temperature is less than 120 degrees, and the dust removal equipment bag has a service life of more than 2 times longer, which meets environmental protection requirements.

- Widely applicable: It can be used to dry raw materials such as yellow sand, river sand, quartz sand, slag, clay, etc., and is widely used in building materials, chemicals, casting and other industries.

- Advanced design: Made of wear-resistant manganese plate, it is 3-4 times more wear-resistant than ordinary steel plate; there is no air leakage, which completely solves the sealing difficulty.

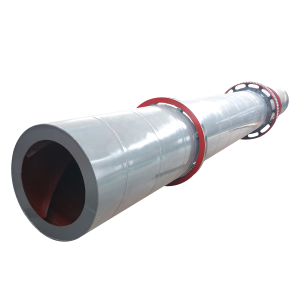

Long rotary dryer

The long rotary dryer rotates the cylinder to make the wet material flow inside and contact with the heat carrier in countercurrent, achieving efficient drying. It has the characteristics of high productivity, high drying intensity, short time, simple structure, large processing capacity and high thermal efficiency.

Features of long rotary dryer:

- Efficient production: materials are added from the high end and discharged from the low end, and the heat carrier is recycled and reused at the same time, which improves production efficiency.

- Wide application: It is an ideal equipment for industrial drying and is widely used in the drying of various materials.

Airflow dryer

Airflow dryer, also known as hot air pipeline dryer, is a device that uses the principle of hot air pulse drying. It has the advantages of direct heating, fast drying, foldable installation, and space-saving.

Features of airflow dryer:

- Direct heating: Directly use hot air flow to heat and dry materials, and the drying speed is fast.

- Space saving: Foldable installation, easy to store and transport, saving space.

- Wide application: Suitable for food, feed, chemical, pharmaceutical, mining and other industries, for drying powdered, flaky, and heat-sensitive materials.

- Digital information:

Fuel selection:

Firewood (chopped wood), coal, steam or electric heating can be selected.

In conclusion

- The three-pass dryer is widely used in building materials, chemicals, casting, and other industries due to its high efficiency, energy saving, environmental protection, and wide applicability.

- The long-drum dryer occupies an important position in the field of industrial drying due to its efficient production, simple structure, and wide application.

- The airflow dryer is favored in food, feed, chemical, and other industries due to its direct heating, fast drying, and space-saving characteristics.

|

Model

|

Diameter of outer cylinder(m)

|

Length of outer cylinder

|

Drum volume (m3)

|

Rotation speed(r/min)

|

Max air flow temperature(℃)

|

Production capacity(t/h)

|

Power (kw)

|

| (m) | |||||||

|

2.0*4m

|

2

|

4

|

12.56

|

4-10

|

700-750

|

8-15

|

5.5*2

|

|

2.2*5m

|

2.2

|

5

|

18.99

|

4-10

|

700-750

|

12-20

|

5.5*2

|

|

2.5*6m

|

2.5

|

6

|

29.43

|

4-10

|

700-750

|

18-28

|

7.5*2

|

|

2.8*6m

|

2.8

|

6

|

36.92

|

4-10

|

700-750

|

25-35

|

11*2

|

|

3.0*6m

|

3

|

6

|

42.39

|

4-10

|

700-750

|

30-40

|

7.5*4

|

|

3.0*7m

|

3

|

7

|

49.45

|

4-10

|

700-750

|

30-45

|

7.5*4

|

|

3.2*7m

|

3.2

|

7

|

56.27

|

4-10

|

700-750

|

35-55

|

11*4

|

|

3.6*8m

|

3.6

|

8

|

81.39

|

4-10

|

700-750

|

55-75

|

18.5*4

|

|

4.0*10m

|

4

|

10

|

125.6

|

4-10

|

700-750

|

70-100

|

22*4

|

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.