Glass Crusher

- Type: Hammer Crusher

- Input: Below 250mm, output: below 19mm

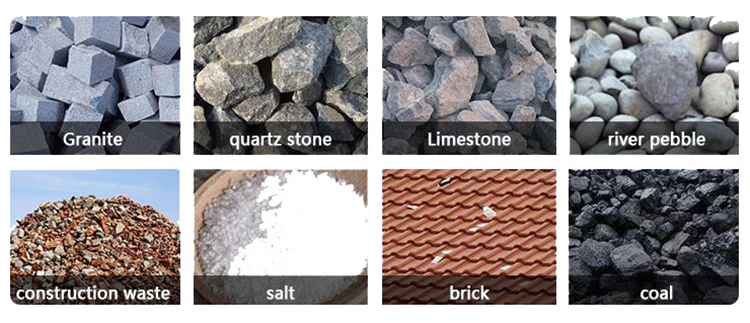

- Processed material: Coal, limestone, gypsum, chalk, alum, salt, brick, etc., mainly to impact and grinding stripping material material crushing materials.

- Application: Applied in the mining, cement, coal, metallurgy, construction, road building, and petroleum and chemical industries

Efficient glass crusher features:

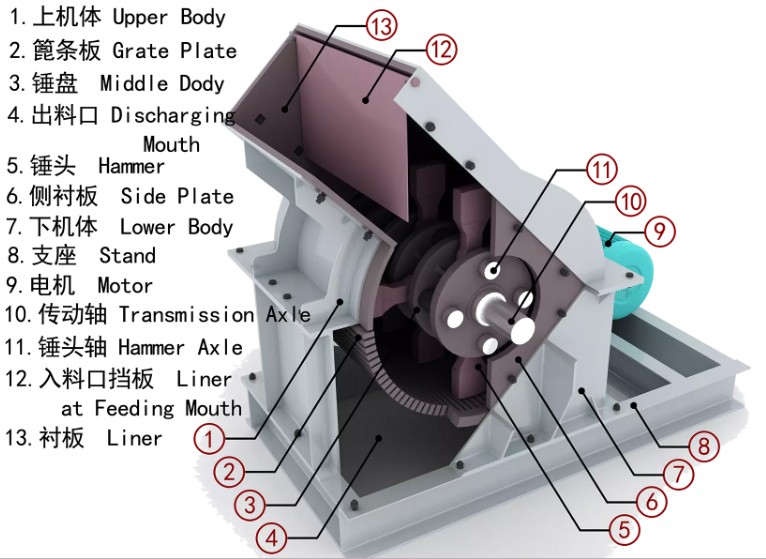

• Efficient hard stone mini glass crusher is composed of machine box, rotor, hammer, impacting lining board, and screen board.

• The main working part of hammer crusher is the rotors with the hammer. The rotors consist of a main shaft, disk, pin shaft and hammers.

• The motor drives the rotors to rotate quickly in the crushing cavity. Raw materials enter the crusher through the feed opening and are stricken, impacted, cut, and ground by the high-speed hammer to a small size

• According to the requirements of the customers, this equipment can adjust the gap between the grating bars to change the discharging granularity.

Main parts of glass crusher:

Main Frame

The lower part is made of carbon constructional steel plate. To place the bearing for the rotor support, high manganese steel is specially adapted to compose the bearing support.

Liner plate and impact plate

A liner plate made of manganese steel is designed on the inner wall of the main frame. The impact plate is also composed of high manganese steel to ensure its abrasive resistance and impact resistance.

Rotor

The rotor consists of the main shaft, hammer plate, hinge pin, hammerhead, etc. The rotor shows high durability. The hammer head is made of multi-element steel with high chromium and manganese.

So, the working life of the hammerhead is much longer.

Screen

Screen is used to check whether the material reaches the required fineness or not. When reaching the required fineness, the material acts as the final product and is dis-charged from the outlet.

| Model | PC0203 |

| Feeding Size | ≤150 mm or Dia. 150 mm |

| Output Size | 0.5-1 mm (As requested) |

| Capacity | About 1000 kg per hour |

| Motor | 5.5 Kw (3 Phase,380V,50HZ, or As requested) |

| Quantity of Crushing Hammer Head | 9 units |

| Working Diameter of Crushing Rotor | 200 mm |

| Length of Crushing Rotor | 300 mm |

| Overall Size | 1600x700x1200 mm |

| Weight | 750 KG |

| No-Load Noise | In 1meter ≦75 db.(A) |

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.