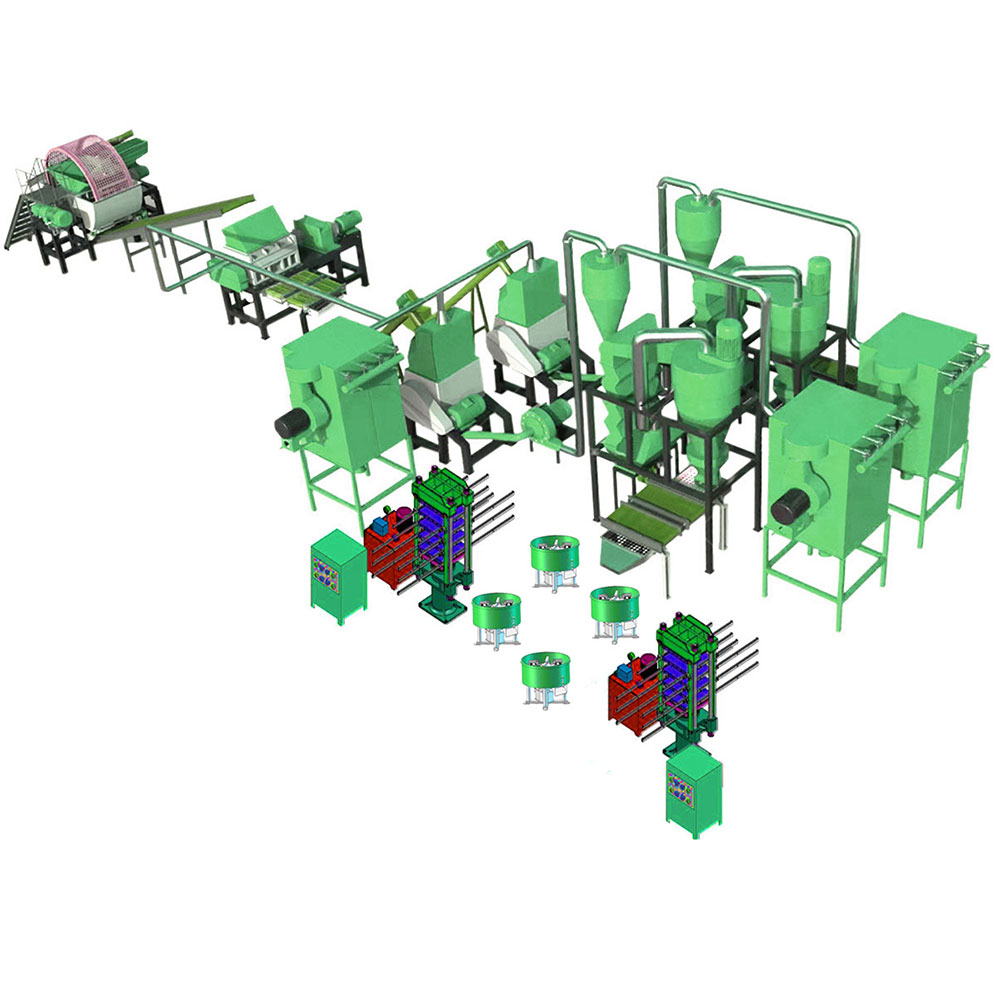

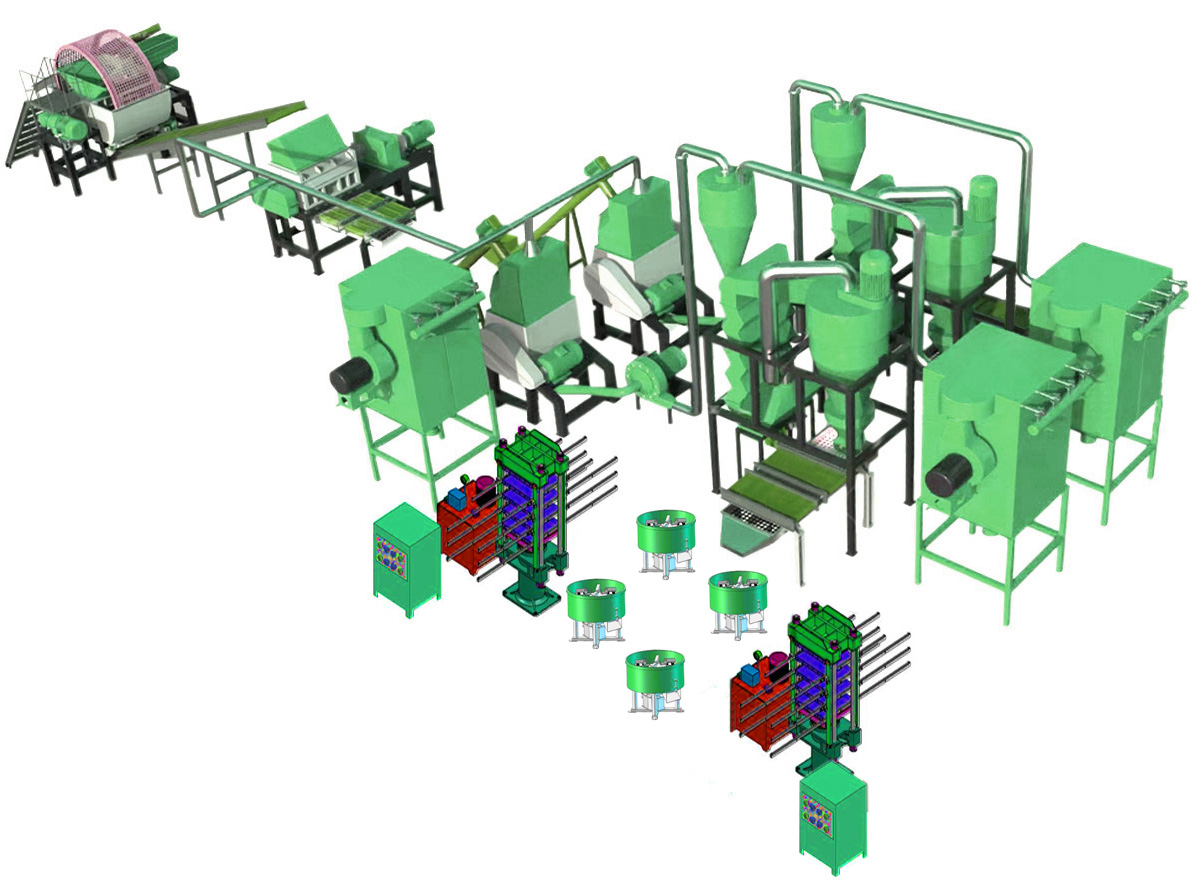

Recycled Rubber Making Product Plant

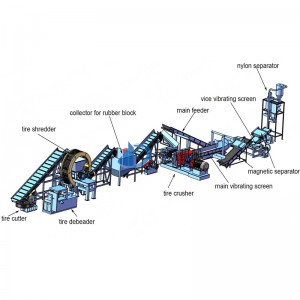

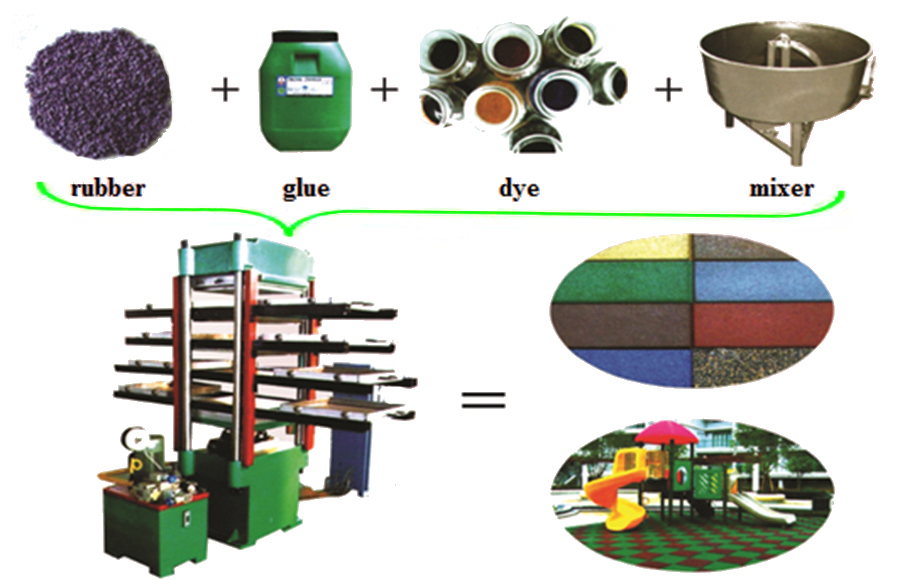

The rubber product production line uses the recycled rubber from waste tires to make new rubber products or reuse the recycled rubber. It mainly uses the recycled rubber to make rubber tiles, rubber bricks, rubber mats, or pave rubber roads, wall and so on.

The complete recycled rubber making product plant also uses a lot of rubber machinery to complete the production. Like rubber bonding mixer, rubber coloring pigment mixer, hydraulic rubber extrusion molding machine, or paving machine, etc.

Rubber Mixer

Rubber Glue Mixer mainly mixes the recycled rubber and organic harmless curing agent according to certain proportions and requirements until they are uniform.

Coloring Pigment can be added to the recycled rubber particles according to the usage scenarios of rubber products, stirred into different colors, and rubber products of different colors can be made.

Hydraulic Rubber Extrusion Molding Machine

The hydraulic rubber molding machine spreads the mixed recycled rubber evenly in the molding machine mold one by one and compacts it. The machine automation function is started to make the recycled rubber in the mold into the required rubber tiles, rubber bricks, rubber mats through extrusion and high temperature.

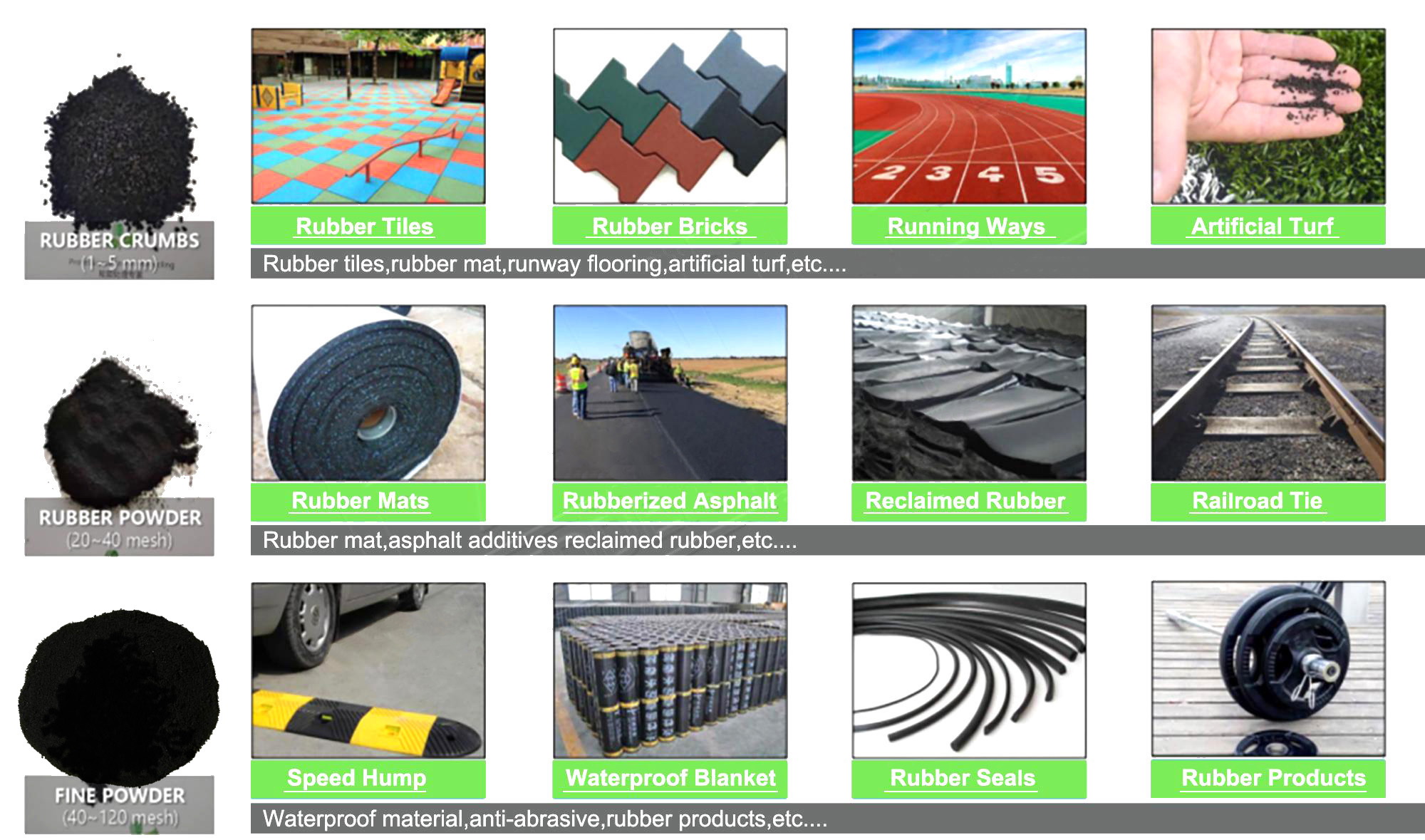

Recycling Rubber Products Display

We are building a sustainable future with the Tire Recycling Plant. Final products are for infill artificial grass, poured in place, bark for mulch - colored rubber granules, rubber athletic tracks, rubber tennis courts, rubber bowls courts, rubber paratroopers, rubber building soundproofing, rubber playgrounds, rubber pavement, traffic warning products, sports products, new tires and so on.

| Type | Model | Mould Size | Pressure | Motor |

| Single Layer Machine | Single Mode | Customizable As Requested | 100-500 Ton | Motor Power is Designed According To Mold Size And Pressure |

| Complex Mode | ||||

| Multilayer Machine | Single Mode | 50-200 Ton | ||

| Complex Mode |

Effects of recycled rubber making product plant:

Common rubber products produced in these lines include:

> Tires: For automobiles, motorcycles, bicycles, and other vehicles.

> Rubber mats: Used in homes, offices, and industrial settings.

> Rubber seals and gaskets: For various applications, including automotive, industrial, and construction.

> Rubber hoses: Used in various industries, including automotive, hydraulic, and pneumatic systems.

> Rubber flooring: For residential, commercial, and industrial spaces.

> Rubber toys and sporting goods: Such as balls, gloves, and mats.

By utilizing recycled rubber, rubber product production lines contribute to waste reduction, energy conservation, and environmental sustainability. They also offer a valuable solution for managing waste tires, which can pose environmental challenges if not properly disposed of.

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.