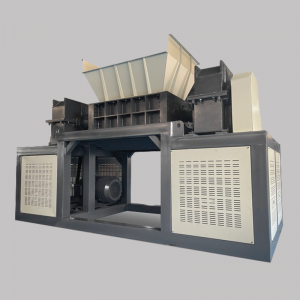

Cardboard Shredder

Corrugated Cardboard Shredders crush and shred corrugated cardboard, whether flat, boxed, or cores. They are available in various horsepower to meet your corrugated cardboard size-reduction requirements for further processing.

Cardboard Shredders have standard throat widths that range from 48″ to 60″ wide. Their throughput ranges from 1-10 tons per hour, depending on the density and corrugated being processed.

Depending on your needs, Cardboard Shredders may require a dual-shaft shredder, triple-shaft shredder, or quad-shaft shredder.

A cardboard shredder can turn a chunk of kraft paper into pieces. Recycling cardboard could save money on packaging costs. The waste would normally be transported to the shredder from departments and destroyed in a single location. These carton shredders will shred between 400kg -3000kg of waste per hour and deliver 40mm by 40mm pieces.

Benefits of Adopting Carton Shredder

- An industrial shredder on an industrial and commercial scale can process cardboard waste and paper products in a large quantity.

- A heavy-duty shredder can work with a dust collection vacuum.

- A cardboard or paper shredder enables you to dispose of this real quick.

- Recycle cardboard more efficiently.

- Safely destroy voluminous waste and confidential documents.

- Save your valuable time to do the shredding, and the shredder machine is easy to operate and manage.

- Cardboard shredder machine is for sale in Wiscon. We are a manufacturer of industrial shredders and we export shredder machines to all over the world including the U.S., Canada and the U.K.

Applications of Cardboard Shredder

We empower you not merely for cardboard shredding, but also for the following waste.

- Corrugated box

- Paperboard

- Carton box

- Cardboard and corrugated cardboard

- Juicebox

- Paper-based products

|

Model

|

600-300-44-HD

|

800-400-60-HD

|

900-400-74-HD

|

1000-450-45-HD

|

1200-500-110-HD

|

1400-600-150-HD

|

|

Shredding Box

|

Adopts Upper And Lower Shells, Steel Plate Bolted Structure

|

|||||

|

Size of Feeding Port(mm)

|

1000×800

|

12000×1000

|

1300×1000

|

1400×1100

|

1600×1200

|

1800×1400

|

|

Working Capacity(T/H)

|

About 1

|

About 2

|

About 3

|

About 4

|

About 6

|

About 10

|

|

Rotational Speed

|

9-12 r/min (according to shredding material)

|

|||||

|

Shredder Structure

|

Square Steel Pipe, Steel Plate, Casting Parts

|

|||||

|

Weight(Kg)

|

3200

|

4300

|

5800

|

8600

|

12500

|

15700

|

|

Hardness of Blade

|

HRC50°- HRC55°

|

|||||

|

Type of Blade

|

Outer Multi-Toothed, Inner Hexagon

|

|||||

|

No-Load Noise

|

In 1meter ≦75 db.(A)

|

|||||

Q1: Who are we?

A: We are Di Hai Machinery and based in Henan, China, start from 1990, sell to Southeast Asia(35.00%), Africa (20.00%), South America(20.00%), Eastern Asia(18.00%), Mid East(7.00%). There are a total of about 51-100 people in our office.

Q2: How to ensure the quality of the products used by your company?

A: All materials in our company are by national standards and design requirements, clear quality standards, strengthened supply chain management, strict control procedures, comprehensive testing and customer feedback, and improved employee quality awareness.

Q3: What can you buy from us?

Recycling machines, including baler machines, shredder machines, crusher machines, tire recycling plants, plastic recycling plants, metal recycling plants, wood recycling plants, copper recycling plants, battery recycling plants, and paper tray-making plants.

Q4: Why should you buy from us not from other suppliers?

We have 20 years of experience in design and development, With rich experience in import and export trade. Installed and debugged locally, to teach technology, training, and maintenance of equipment. Guarantee on-time delivery according to contract requirements.

Q5: What services can we provide?

- Accepted Delivery Terms: FOB, CFR, EXW;

- Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

- Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

- Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.

Q6: Why Choose Us?

- Several Year’s Experience We have rich experience in equipment manufacturing and our products have a high reputation both at home and abroad.

- Manufacturer, Not Dealer Factory direct sale makes the price more competitive. Customers are always welcome to visit our factory for machine tests.

- Fast Delivery We promise the goods can be shipped out on the delivery date after confirmation of the order.

Q7: When we only purchase one shredding production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q8: Which brand of motor will you use?

A: We use Siemens or other High quality well-known brand.

Q9: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer’s requirement, we will dispatch engineers to guide installation and training about the operation of the machine and we also provide online remote instruction.